Construction and Maintenance of Road Marking Glass Beads: How to Ensure Long-Term Reflective Performance Stability?

2025-06-21

Road marking glass beads are essential for ensuring the reflective performance and nighttime visibility of road markings. To ensure their long-term reflective performance stability, a series of measures must be taken during both construction and maintenance. Here are the key points to help ensure the long-term stability of road marking glass beads:

1. Preparation Work Before Construction

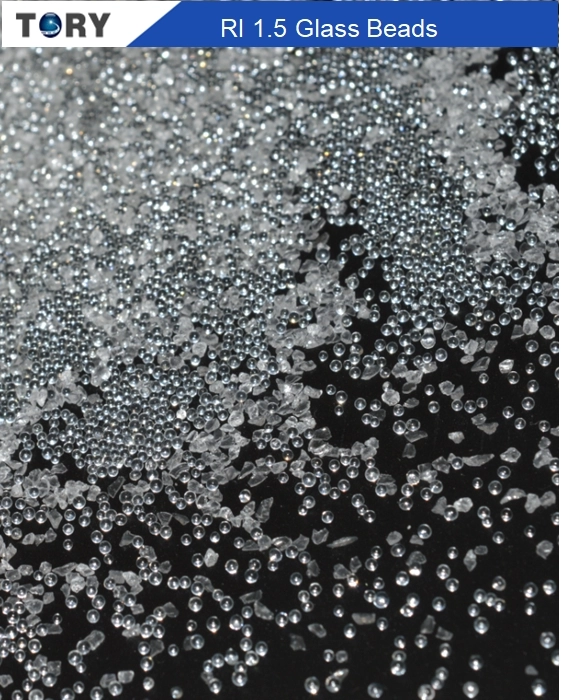

- Select High-Quality Glass Beads: Choose glass beads with high reflectivity, abrasion resistance, and weathering resistance to ensure they maintain their reflective performance over time. High-quality glass beads typically have good UV resistance and high-temperature resistance, which are critical for maintaining long-term reflective performance.

- Appropriate Glass Bead Size: Different environments require different sizes of glass beads for road markings. In wet conditions, smaller beads may offer better reflective performance, while larger beads are more abrasion-resistant for high-temperature and high-traffic areas. Choosing the appropriate bead size based on the road environment can significantly improve reflective performance.

- Ensure Clean Surface: Before applying the road markings, the road surface must be clean, free from oil, dust, or debris, to ensure that the glass beads adhere properly to the marking paint, guaranteeing long-lasting effectiveness.

2. Proper Construction Techniques

- Uniform Application of Glass Beads: During construction, the glass beads must be evenly distributed on the paint surface of the road markings. The number and uniformity of the beads directly affect the reflective performance. Too few beads will lead to poor reflection, while too many may cause the beads to become loose and unstable, which can reduce the durability of the markings.

- Appropriate Paint Thickness: The thickness of the coating layer affects the adhesion of the glass beads and their reflective performance. If the layer is too thin, the glass beads may fall off, while a too-thick layer may affect the exposure of the beads, which reduces their reflective properties.

- Temperature Control: The environmental temperature during construction must be appropriate. If the temperature is too low, the paint may not dry properly, reducing the adhesion of the glass beads. If the temperature is too high, the paint may dry too quickly, preventing the glass beads from properly embedding in the coating. Suitable temperatures ensure proper adhesion of the beads.

3. Maintenance Measures

- Regular Inspection: The reflective performance of road markings declines over time, so regular inspection of the markings, especially in high-traffic and harsh weather areas, is essential. During inspections, the brightness, uniformity, and wear of the markings should be checked.

- Timely Replenishment of Glass Beads: If it is found that glass beads are missing or severely worn during inspections, they should be replenished promptly. This can be done by adding new glass beads or reapplying the markings to restore their reflective properties.

- Cleaning and Maintenance: Dirt, oil, snow, and other debris on road markings can impair the reflective performance of the glass beads. Therefore, regular cleaning of the road markings is essential. Specialized cleaning equipment and methods should be used to ensure that the beads are not covered and that their reflective performance is maintained.

- Avoid Mechanical Damage: Road markings are often subjected to friction from vehicle tires and compression from traffic, which can lead to the wear or removal of glass beads. To reduce such damage, regular road surface checks should be conducted, and damaged markings should be promptly repaired, especially after traffic peaks or harsh weather conditions.

4. Impact of Climatic and Environmental Factors

- Adapt to Extreme Weather Conditions: Climatic differences in different regions can affect the performance of road marking glass beads. For example, in high-temperature areas, the high-temperature resistance of the beads becomes particularly important, while in cold regions, frost resistance is crucial. During construction, it is essential to select appropriate glass beads and paint according to the climate conditions.

- Avoid Chemical Contamination: Some chemicals, such as road salt and solvents, may corrode road markings and impair the reflective performance of glass beads. Therefore, excessive use of deicing salt should be avoided in winter, and roads should be regularly cleaned in other seasons to maintain the best performance of the beads.

5. Use of New Technologies and Materials

- Nanotechnology and Glass Beads: With advancements in technology, nanotechnology has been applied to the manufacture of road marking glass beads. Nanoglass beads have better reflective performance and are more abrasion-resistant than traditional glass beads, allowing them to maintain long-term reflective performance in harsher environments.

- Self-Healing Markings: In recent years, the combination of self-healing coatings and glass beads has been applied to road markings. These coatings can self-repair when the surface is damaged, extending the lifespan of the markings and maintaining reflective performance.

Ensuring the long-term stability of road marking glass beads’ reflective performance requires not only the use of high-quality beads but also careful attention to construction techniques and ongoing maintenance. Regular inspections and timely repairs, combined with new technologies and materials, can effectively improve the reflective performance of road markings and ensure road safety and visibility. Furthermore, considering the impact of climate and environmental factors can ensure the glass beads continue to perform optimally under various conditions. By implementing a comprehensive approach, the lifespan of road marking glass beads can be extended, maintaining road safety and visibility.