- Tel : 86 552 7165551

- Email : echo@cntory.com

- Skype :echotory@hotmail.com

History of Glass

Beads for Road Markings

Glass

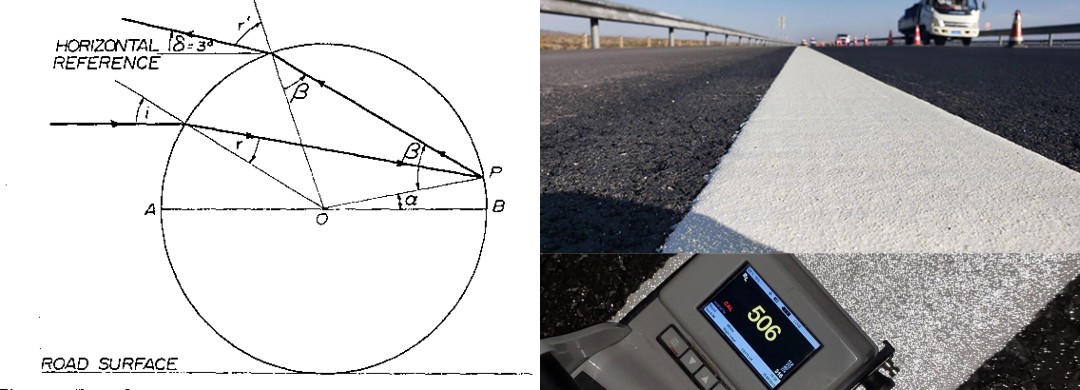

beads have always been used to make reflective road signs. If properly embedded

in the marking material, the glass beads are able to collect the incident light

and reflect some of it back to the light source. It's this ability that makes

these small, spherical glass particles unique.

1952: Pocock and Rhodes first studied the principle of glass bead retroreflection.

1967: Dale

demonstrated in the NCHRP report and recommended the use of larger size glass

beads.

1969: Dale

first proposed the best retroreflection of dry and wet reflective marking and

glass bead settlement of 60%.

1976: DaForno

of Potters presented a comparison of adhesion of glass bead coatings and marking

coatings at the TRB annual meeting.

The

surface treatment of AC-04 improved the bead-coating adhesion 5 times more than

that of moisture-proof glass beads, and 25% better than the uncoated glass

beads.

The

surface treatment of AC-02 improved the bead-coating adhesion by 10 times

compared with the moisture-proof glass beads, and was 50% better than the

uncoated beads.

Note:

AC-4, AC-2 adopt different coating processes for different marking materials

(such as hot melt, epoxy, PMMA, etc.)

1984:Larger glass

beads were tested in laboratories and field testing sites in northern New

Jersey, providing reflectivity 3-4 times higher than standard beads. And for

the first time, the 350 mcd road marking was proposed to provide drivers with more

clear guidance.

1986: Timely evaluation of installation with retroreflectometer with the active

cooperation of Maryland Department of Transportation. During initial and

subsequent evaluations, larger beads proved to be more retroreflective.

1987: Preliminary

field trials of large particle size glass beads were conducted in New Jersey.

Actual field applications are carried out with thin film materials (epoxy

resins) and thick film materials (hot melt coatings, polymethyl methacrylate

(PMMA) of less than 20 mil in order to optimize glass bead adhesive systems.

Changes in adhesive film thickness, glass bead size, and glass bead surface

treatment were evaluated, and reflectivity, durability, and night performance

on wet roads were evaluated with portable reversemeters.

March 1987: Painting

was done using hot melt type paint according to Florida codes, and a year later

a local observer evaluated the site and noted that the site was wet reflective.

August 1987: On a

four-lane highway in California. Using a hot melt paint with large particle

size glass beads, the site was observed to provide good wet reflection

performance 6 months after installation.

In

conclusion,high

quality reflective road markings can bring more safety to pedestrians and

drivers. Glass beads are a key factor in

ensuring visibility of road markings at night. The ultimate purpose of

installing and maintaining road markings is to improve road safety; for this,

high-quality raw traffic safety materials are essential.

Tory, as a leading manufacturer of glass beads for road markings with more than 30 years-experience,

is dedicated to renovating technology and keeping quality high. Tory is glad to

offer help if you need glass beads for road markings. And all products can be customized according to

customer requirements. For more information, or to get started on your traffic safety solution: https://www.cntory.com/

Feel free to contact us:

Email: Echo@cntory.com

WhatsAPP: +8617355287086

scan to wechat: