Characteristics and Applications of Two-Component Road Marking Paint

2025-10-24

Table of Contents

Two-component road marking paint is a cold-molded product based on methyl methacrylate resin system. With solvent-free formula,it owns excellent anti-skid and high wear resistance properties so as to possess long marking life and good reflective effect on rainy nights.

1、Durability

The molecular weight of the individual components is very small, which makes the markings have good permeability before the polymerization chemical reaction occurs; during the condensation process of the markings, the two components undergo polymerization chemical reactions, making the markings and the road surface strong bond.

2、Strong wear resistance

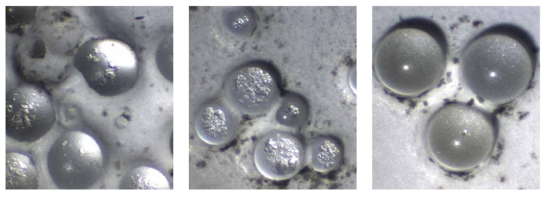

The polymerization reaction of the two components forms a network molecular structure. Each component in the paint is closely combined into a dense whole, that is, the network molecular structure formed by the two components makes it a polymer material with an extra-large molecular weight. Road marking paint made of polymer materials not only has super strong adhesion on asphalt pavement, but also has super strong adhesion on cement pavement, stone pavement, ceramic tile floor, and even glass.

3、Strong weather resistance

Two-component road marking paint is not prone to low-temperature fracture or high-temperature softening, and has almost no aging during use, because the new network molecules formed after the polymerization reaction of the two components are polymers with extremely large molecular weights, and the new molecules do not contain active molecules. The thickness of the markings can be between 0.4 and 3.0mm, and the optimal thickness can be selected according to actual road conditions and traffic volume.

In contrast, raised profile markings made of hot-melt materials soften due to high temperatures in summer and the protruding parts are squashed; cracks appear in winter and the protruding parts are easily impacted off. The two-component road markings are very stable in terms of physical and chemical properties at high or low temperatures. Therefore, raised profile markings made of two-component paint have excellent weather resistance.

4、Reflectivity

Room-temperature acrylic markings can hardly be used as reflective markings because the markings they draw form a film and the glass beads cannot effectively adhere. Hot-melt markings have relatively poor reflective effect and short lifespan. First, because it is combined with the ground under high-temperature cooling conditions, that is, in summer, the cooling time of the paint is too long, and the glass beads easily sink to the bottom of the marking; in winter, the cooling time of the paint is short, and the glass beads cannot sink to the bottom of the marking with effective depth, resulting in poor reflective effect. Second, the hot-melt coating itself has low strength and is prone to aging, so that the glass beads cannot effectively combine with the painting.

5、Anti-Pollution

The hardness of the hot-melt marking material is low, and it is easy to soften at high temperatures in summer, and contaminants can easily enter the inside of the markings; while it is easy to crack at low temperatures, causing crack contamination. In cold-molded two-component markings, the two components undergo a polymerization chemical reaction to form a network polymer structure, which is a dense whole. The paint film is smooth, dense, and strong, and does not change sharply with temperature changes. The performance is relatively stable from 100℃ to minus 30℃.

6、Economy

Two-component road markings have a long service life and low maintenance and construction costs; there is no aging phenomenon in the markings, and re-construction is only to achieve aesthetic effects, without the need to clean up the old lines; the construction efficiency is high and losses caused by various hidden dangers are avoided.

7、Construction suitability

Acrylic marking paint at room temperature has poor construction applicability and cannot be constructed below 5°C. Moreover, due to the high flux content, it brings fire hazards to the construction. The construction adaptability of hot-melt markings is also very poor. It requires construction above 15℃. If the construction is done at high temperature, the cooling time will be long, and the glass beads will easily sink, affecting traffic and reflective effects; if the construction is done at low temperature, the cooling will be too fast, and the paint will not be able to effectively penetrate the ground, and the adhesion will decrease, and the glass beads cannot sink effectively and easily falls off. It also requires liquefied gas to be heated to a high temperature of 200°C, which brings explosion and fire hazards to the construction. As a cold molding product, the two-component road marking paint has excellent construction applicability and is suitable for construction under ambient temperature conditions of -5 to 35°C. By artificially adjusting the amount of chemical catalysts added, it can be fully realized at different temperatures. The curing time is controlled; the construction process is semi-mechanized and highly efficient; the paint contains almost no flux, is not easy to burn, and does not require heating, ensuring construction safety.

8、Environmental protection

Normal temperature acrylic marking paint will evaporate 30% of the flux into the atmosphere, directly causing pollution; although normal temperature water-soluble paint is very environmentally friendly, the volatilization of water in waterborne paint also requires the carrying of flux, so a large part of the flux will also volatilize into the atmosphere, causing pollution. The resin of hot-melt marking paint volatilizes during the heating process. At the same time, during the construction process, the carbon dioxide and carbon monoxide produced by the combustion of liquefied petroleum gas volatilize into the atmosphere, causing pollution.

The two-component road marking paint does not contain any flux. The irregular network structure composed of ultra-long chain segments formed by the polymerization chemical reaction is very strong and environmentally friendly. It adopts normal temperature construction without heating, which greatly reduces energy consumption and atmospheric pollution during construction.

The ultimate purpose of installing and maintaining road markings is to improve road safety; for this, high-quality raw traffic safety materials are essential.