- Tel : 86 552 7165551

- Email : echo@cntory.com

- Skype :echotory@hotmail.com

Introduction of Common Defective Glass Beads

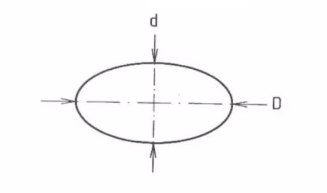

Ⅰ.Oval glass beads (see Figure 1)

When the ratio of the major diameter D to the minor diameter d is greater than 1.3 (D/d >1.3), the oval glass bead shall be considered defective.

Figure 1- Oval Glass Beads

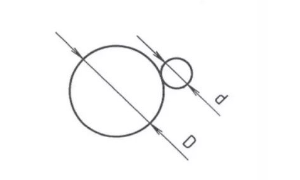

Ⅱ. Satellites (see Figure 2)

When a glass bead supports more than two smaller glass beads, called satellites, or when, in the case of two satellites, the ratio of the diameter d of the major of them to the diameter D of the supporting glass bead is greater than 0,25 (d/D > 0.25 ), the glass bead shall be considered defective.

Figure 2- Satellite

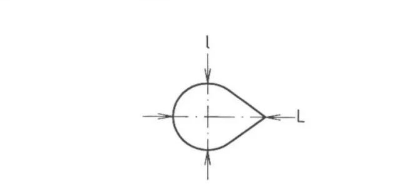

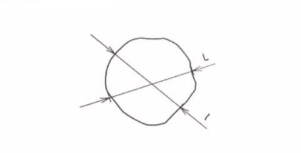

Ⅲ. Tear shaped glass beads (see Figure 3)

When the ratio of the major dimension L to the minor dimension l is greater than1.3 (L/l>1.3), the glass bead shall be considered defective.

Figure 3- Tear shaped glass beads

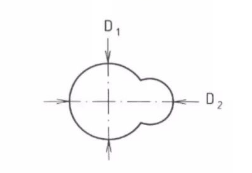

Ⅳ. Glass beads fused together(see Figure 4)

When the ratio of the major dimension D2 to the minor dimension D1 is greater than 1.3(D2/D1 > 1.3), the particle shall be considered a defective glass bead.

Figure 4- Glass beads fused together

Ⅴ. Roundish glass beads (see Figure 5)

When the ratio of their major dimension L to the minor dimension l is greater than 1.3 (L/l > 1.3), the glass bead shall be considered defective.

Figure 5-Roundish glass beads

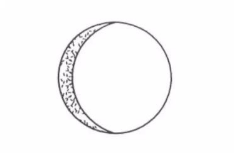

Ⅵ. Opaque glass beads (see Figure 6)

Opaque glass beads shall always be considered defective.

Figure 6- Opaque glass beads

Ⅶ. Milky glass beads (see Figure 7)

The milky appearance is due to gaseous inclusions in part or in the whole volume of the bead. Milky glass beads shall always be considered defective.

Figure 7- Milky glass beads

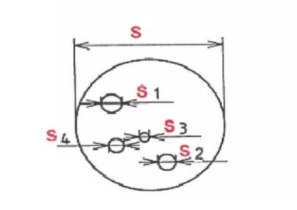

Ⅷ. Gas inclusions (see Figure 8)

When the ratio of the sum of the projected area of the bubbles inside a glass beads ∑s¡ to the projected area of the glass bead S is greater than 0.25 (∑s¡/S > 0.25), the glass bead shall be considered defective.

Figure 8- Gas inclusions

Ⅸ. Grains (see Figure 9)

Glass particles which present one or more sharp angles shall be considered defective glass beads.

Figure 9- Grains

Ⅹ. 10 Foreign particles

Particles which are not composed of glass shall be considered defective glass beads.

Suggestion: How to use glass beads

a. The internal mixed glass beads should be used for internal mixing of large graded glass beads, such as AASHTO M247 TYPE 3 is more suitable for hot melt reflective marking paint and two-component reflective marking paint. And appropriately add 0.4-0.85 mm grading glass beads. To ensure a high inverse reflectivity coefficient value during use.

b. Grading according to 1.7:1 sieving glass beads, 0.6~1.18mm grading is more suitable for water-based reflective marking and two-component reflective marking surface. 0.6~1.4mm gradation is more suitable for hot melt reflective marking. The grading range of glass beads with special requirements can be increased to 0.6~1.7mm grading to ensure the initial retroreflectivity coefficient and its continuity.

In conclusion,high quality reflective road markings can bring more safety to pedestrians and drivers. Glass beads are a key factor in ensuring visibility of road markings at night. The ultimate purpose of installing and maintaining road markings is to improve road safety; for this, high-quality raw traffic safety materials are essential.

Tory, as a leading manufacturer of glass beads for road markings with more than 30 years-experience, is dedicated to renovating technology and keeping quality high. Tory is glad to offer help if you need glass beads for road markings. And all products can be customized according to customer requirements. For more information, or to get started on your traffic safety solution: https://www.cntory.com/

Feel free to contact us:

Email: Echo@cntory.com

WhatsAPP: +8617355287086

scan to wechat: